Refining the Skills of Dickerson Harbor Boatyard Team

We aim to be the best quality yacht repair and modernization facility on the Chesapeake Bay

Having the right equipment improves efficiency and reduces stress on team members. We have an airplane tug and a dozer that provide the appropriate horsepower to move boats on the two hydraulic trailers. With these trailers, we can situate vessels precisely. We also have the electric “Centaur;” half-man, half-pony, to move the light to moderate equipment, tools, shafts, propellers, and boat stands around the yard ASAP!

Fiberglass Work from New Thrusters to Major Hull Accident Repairs

Maintenance Reduction to Extend the Life of Fine Grand Banks, Eastbay or Any Fine Yacht

Veneer Repairs and Replacement to Sustain the Pure Beauty of Classic Grand Banks and Eastbay Yachts

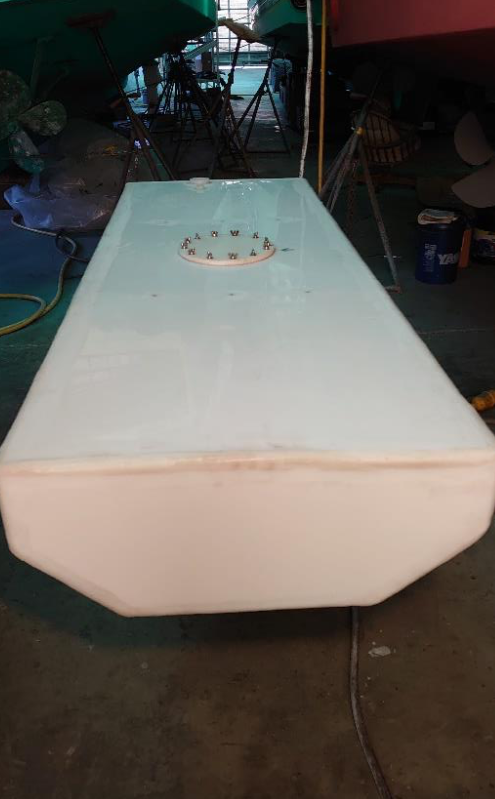

Fuel and Water Tank Replacement on Hundreds of Grand Banks Yachts

Custom Hardtops For UV Protection and Long Life Improvements

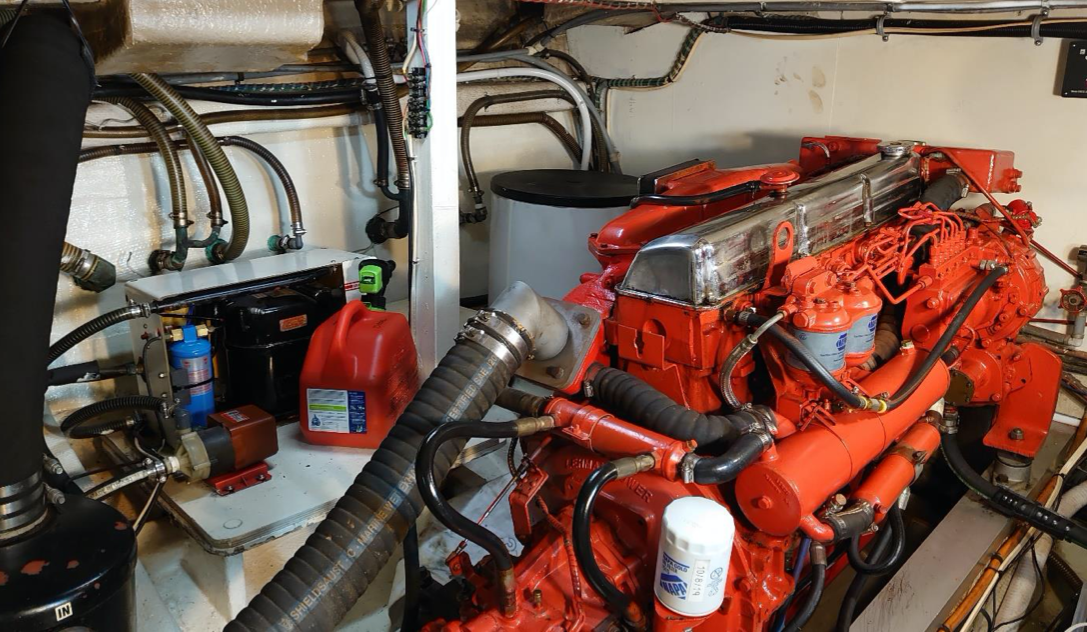

Engine, Hull, and Mechanical Systems Services

Our CAT trained mechanic has over 30 years of experience with marine engines. We routinely provide complete engine room and drive train maintenance and repower projects. We replace hoses, install generator sound shields, recondition and align shafts, shaft seals, and propellers. First, however, we diagnose mechanical and system problems.

Brightwork Makes Grand Banks and Eastbay Yachts Spectacularly Beautiful

Our varnish department produces outstanding finishes with modern Petit Ultra UV coatings and products.