Building Out Dickerson Harbor for Grand Banks Yacht Repair and Chesapeake Bay Winter Storage

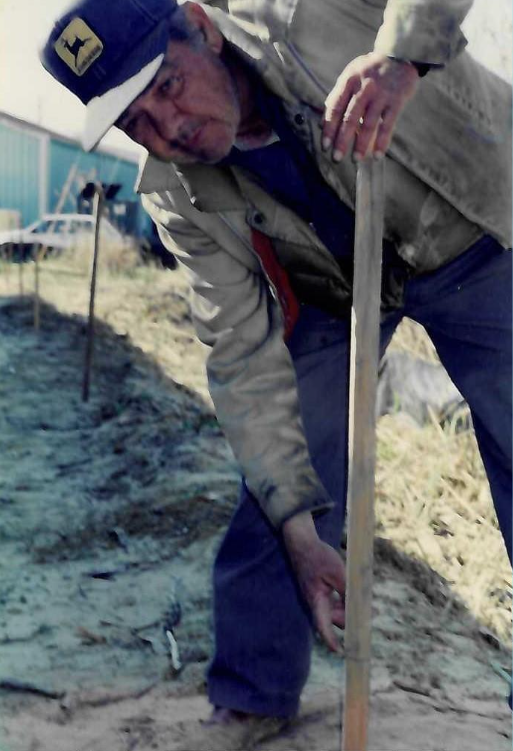

Getting Ready: the site work involved a lot of earth moving!

Through careful planning and the help of a talented contractor named Bucky Osmond, the Dickerson Harbor capabilities were increased

In 1989 the Maryland Legislature passed the “Critical Areas Legislation.” Dickerson Harbor itself is a very sensitive site with its wetlands. The creek and all the species of plants and rare birds that dwell here are sensitive. There was a 15,000-gallon tank farm that held the heating oil used to power the 1,000,000 BTU furnace needed for fiberglass molding by the Lippincotts. The furnace and tanks were removed once they no longer were needed for operations. Dickerson Boatbuilders had two 500-gallon fuel tanks that held diesel and gas for boats in the marina. Both these underground tanks were removed. There were a few barrels of resin in the marsh, ancient houses in disrepair, a sunken garden, and other discoveries to be cleaned up.

Today, we burn waste oil from engine servicing in our specialized heaters to heat the indoor boat storage areas in the winter. We have diesel fuel for our equipment and boats delivered by truck, and there is no need for underground tanks