Sales Preparation

Grand Banks Classic 1984 Maintenance Reduction and Pre-Sale Work Case Study

Welcome to our comprehensive case study on the transformation and eventual sale of a 1984 Grand Banks Classic yacht. In this study, we delve into the meticulous process of preparing this timeless vessel for sale, focusing on maintenance reduction and essential pre-sale work. Maintenance reduction is essential as these Grand Banks yachts approach 40 years of age and more.

There are three usual options for the boat’s condition when it comes time to sell

- Great condition because every maintenance item has been completed when identified by professional technicians.

- Great condition because a lot has been invested in maintenance reduction, so a lot less needs to be done and the owner can keep up with it.

- Poor condition because the owner can’t keep up and can’t afford to have it done professionally.

Despite being initially classified as “Fair” in condition on a pre-sale survey, the yacht faced hull structural issues, a multitude of minor electrical and mechanical deficiencies, and extensive exterior cosmetic challenges. With a willingness to dedicate time and resources to the project, the owner embarked on a journey to enhance the yacht’s appeal, reduce maintenance requirements, and maximize profit upon sale.

This case study offers valuable insights into the transformation of a classic vessel, providing a roadmap for both potential buyers and sellers seeking to navigate similar vessel sales. The yacht will be very fine once the cosmetics and few key maintenance reduction work items are upgraded. The interior is pristine, as is common on many of the Grand Banks yachts, even at 40 years old, if basic window maintenance is performed routinely (no leaks in the cabin).

For any Grand Banks buyer, there are a few areas that need to be carefully checked, as they are common Grand Banks problem areas. These are also major sale-killing items when identified on a survey

- Teak Decks – moisture can penetrate loose seams or missing bungs and be trapped under the deck to penetrate into the plywood which is the strength member in the deck buildup. Once that plywood is rotten, the issue is structural.

- Window frames – these were originally teak and if not maintained can cause leakage, stains, and rot in the cabin.

- Fuel tanks – these are well documented as black iron tanks that can leak from water above because of deck problems or can get pinhole leaks from internal corrosion.

- Water tanks – better constructed with aluminum, many Grand Banks will suffer from pinhole corrosion leaks in these tanks. These are easier to replace but can still be a nuisance. Newer tanks are usually built of sturdy food grade plastic.

- Shafting and bearing issues – Non unique to Grand Banks boats but after years of use these areas should receive close scrutiny on a survey.

- Blisters – these are typical on the 1980s and early 1990s boats until they have been removed, dried out, and had a professional epoxy barrier coating. These are typically not major structural issues but have to be addressed when found.

Engine Room

- Lighting (replace with LED)

- Battery management and wiring (Modernize)

- Shore power wiring

- Hot water heater

- Through-hull valves

- Waterline through-hull fittings

- Heads and holding tanks

- Engine control cables

- Engine sensors to gauges

- Coolant recovery system

- Air separator for older engines

- Transmission to shaft couplings

Salon

- Interior window frame condition

- Window tracks and felt liner

- Door interiors

- Window glass defects (separation)

- Sliding glass components

- Refrigeration

- Headliner

- Engine sensors to gauges

- Veneer from stains

- Salon floor finish condition

Superstructure

- Lazarette hatches (replace plywood core)

- Steps to Flybridge (a common source of deck related issues)

- Cap rail (Allwood or painting)

- Hand safety rail (Allwood or painting)

- Forward and aft cabin hatches

- Eyebrow trim above salon windows and doors (replace with HDPE or paint)

- Full Canvas for Flybridge, rails, and windows

Back to our case study boat, here is the list of major findings on the Pre-Sale survey that resulted in achieving only a “Fair” condition assessment

- Bottom paint was in poor condition and needed to be inspected for blisters. There were in fact blisters later identified on the hull

- The LPG system for the stove had multiple safety issues

- Teak decks were found in poor condition. In particular, the lazarette hatches were soft from plywood rot and needed to be immediately repaired for safety

- Teak steps to the flybridge were in poor condition and needed immediate repair

- All cosmetic exterior teak had been let go to bare wood and needed to be protected

- Operation of the battery charger was questionable

- Anchor chain was in poor condition and needed to be replaced

- Window frames needed to be painted

- Window slides needed to be replaced

- Most aluminum exterior parts like the mast and engine vents needed to be painted

- Headliner in the salon needed replacing

The “sale killer” work items that were addressed included:

- Hull condition and blisters – The boat was left in the yard for a full 12 months to dry out the hull under cover. The paint was blasted off and the hull inspected which did reveal some minor blistering. Those were sanded out and filled once the hull moisture reached an acceptable level of less than 15%. Since the boat was under cover, no further work was undertaken on the hull, it was going to be left to the buyer to apply the barrier coat and bottom paint prior to launching.

- Lazarette hatches were rebuilt using the existing teak deck. This was done with a proven Dickerson Harbor process of carefully removing the teak deck strips, removing all the rotten plywood, replacing that with fiberglass board, and replacing the teak strips with new grooves and sealant. The new hatches match the existing deck perfectly and will last the life of the boat.

- All exterior teak (transom, caprail, handrail, and safety rail) had the old varnish removed and was covered with multiple coats of Cetol for protection until the new owner could decide on a treatment plan (Allwood, varnish, paint or Cetol)

- All fixed window frames were removed to the shop, stripped and painted with 545 primer under Awlgrip GB White

Additional work that was cosmetic or more minor, but priority, mechanical/electrical issues

- The forward and aft cabin hatches interior, runners, and trim were rebuilt

- Window interior parts were prepped for epoxy and varnish. The new buyer had the option to replace the old glass with an upgrade, possibly tinted, or reinstall the existing windows and this was eventually chosen. It’s a very high end look for a minimum investment.

- Cleaned the aft bilges, removed the steering arm planks and replaced the hold down bolts. All bare wood in the Lazarette for tank framing and the steering planks

- All failed light bulbs in the engine room and cabins were replaced

- Work lights and 110V lamps were added to light up the interior

- Fluid was added to the expansion tanks and a pressure check was done on the engines to be sure that would not be a problem on engine survey

- Coolant recovery bottles were repositioned to the proper elevation

- Clamps were replaced on head hoses and others identified in the pre-sale survey

- Engine mounts and stringers were cleaned. Areas around batteries, battery boxes and bilges forward of the holding tank were cleaned

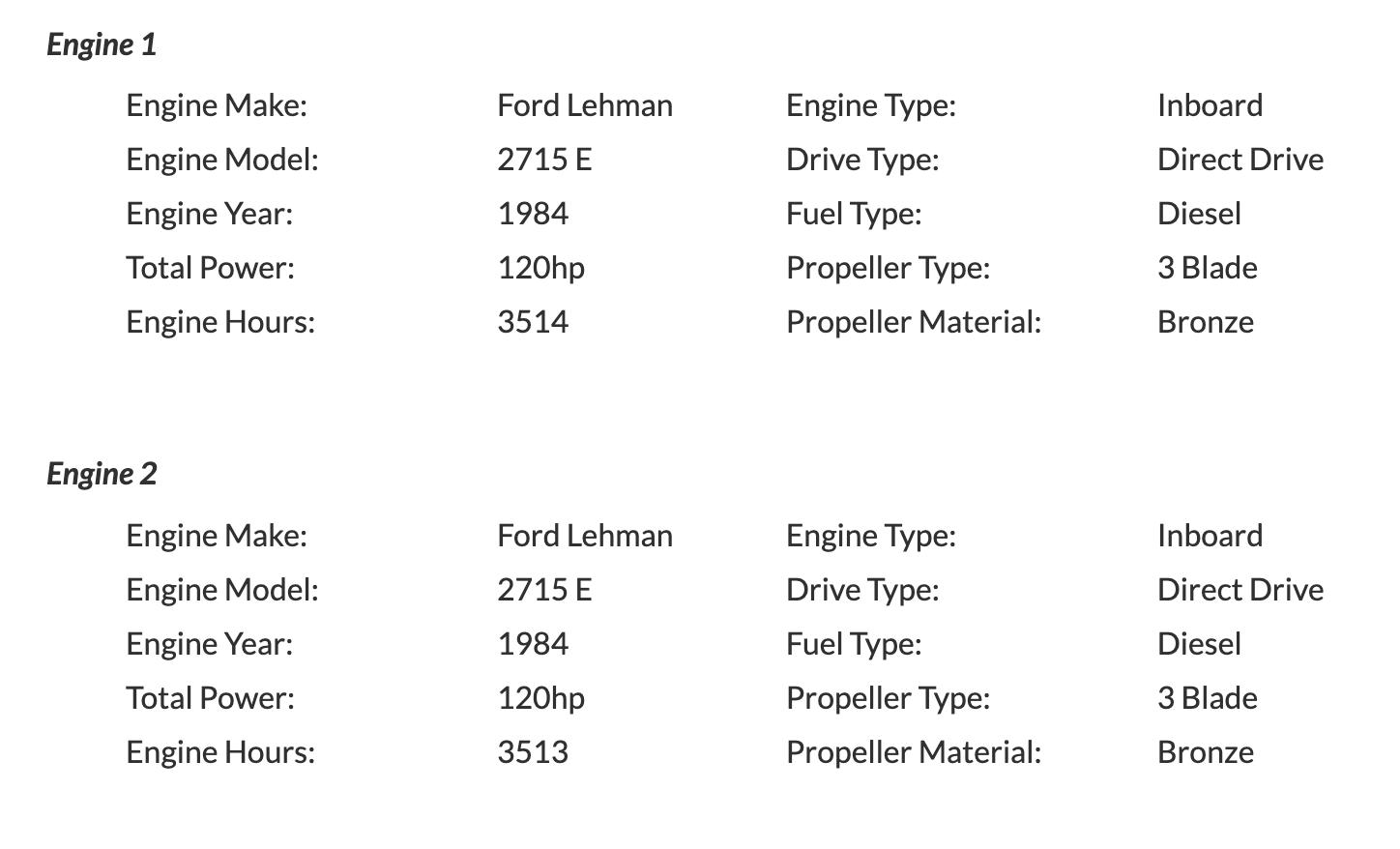

Although these lists may seem daunting, the boat had good “bones” and very high potential to be a fine yacht again. The interior was in excellent condition. The engines had low hours; a lot of mechanical upgrades had been done in the last 5 years. Fuel and water tanks were in good condition despite their age and the shafting system was good for many more years of inland cruising.

This boat had some excellent maintenance reduction and upgrade items already finished. It had new heads, refrigerator, freezer, stove, and icemaker. Holding tank components had been upgraded making it an odorless boat!

Some of the other upgrades the owner had done in the 5 years before the sale included:

- 2018 – New Hot Water Heater – Kuuma 11 Gallon

- 2018 – New Accumulator Tank

- 2019 – New Swim Platform

- 2019 – Windlass Rebuilt

- 2020 – New Engine Mounts on Starboard Engine

- 2020 – New Water Pump Starboard Engine

- 2021 – New Bilge Pumps and wiring

- 2021 – New Electric Heads fore and aft – Raritan & Jabsco

- 2022 – New Fuel Pump on Port Engine

- 2022 – New Oil Cooler lines on the Port Engine

- 2022 – New Batteries – (6) 4D Wet Cell

Here is an excerpt from the listing in Yacht World.

1984 Grand Banks 42 Classic

Our Case Study is a 1984 Grand Banks 42 Classic, with low engine hours, built with a solid fiberglass hull and superstructure, the GB 42 Classic was designed and built for safety, stability, and long-lasting quality on the water. What also sets Our Case Study apart from other GB 42s of the same vintage is the condition of the interior and accommodations. The teak parquet cabin sole and all the interior teak joinery are in good condition. There are updated appliances in the galley and new electric toilets in both heads. New memory foam mattresses on both aft berths and new cushions with new upholstery throughout the salon and in the V-berth show the owner’s attention to comfort and livability. The owner has also invested in new cushions for the flybridge seating.

As is sometimes the case in selling a 40-year-old boat, there was a hiccup on the buyer’s survey. The good news was that all the work had increased the condition assessment on the boat to “Above Average”. Buyer interest was strong, and an offer was eventually worked out but the surveyor identified a section of the flybridge deck that had high moisture on his meter. This is the first time this problem has been identified by our yard and is unusual for a Grand Banks of this vintage. The flybridge decks have a large amount of camber to facilitate quick water drainage to the main deck. This area is also often shaded by a bimini top which reduced the damage the teak deck receives. coreCore samples were taken to, identify the suspect areas and those were rebuilt from inside the salon.

This was a successful sale even though it required a lot of work and some investment by both seller and buyer. wWe consider the pre-sale work to have been very successful. The improved condition found on the buyer’s survey was gratifying and did in fact result in an offer that met the seller’s goal. There is still a lot of work for the new buyer, but they will be getting a fine yacht in solid condition.

The main lessons from this case study are:

- Maintenance Reduction is always preferred to last minute work prior to a sale. The buyer will see the investment and the price will be higher. The owner will have less work to do while they own the boat. It’s win-win.

- Buying an older Grand Banks yacht can be a great investment. The replacement new value for this boat was over $750,000 and could easily have been over $1M. They deserve to be well maintained over their life. We are shooting for the “100 YEAR BOAT” through proper maintenance.

- If you want to sell your boat for “what you paid for it” then investment in maintenance reduction up front and sustained quality maintenance year after year will make that easy.

Contact us at Dickerson Harbor boatyard and The Oxford Yacht Agency at 410-822-8556