Grand Banks Fuel Tank Replacement

So, you have a Grand Banks fuel tank leak or noticeable rust. One of the most frustrating and expensive problems found in all years of Grand Banks yachts is the problem of rusting and leaking fuel tanks that must be replaced.

This is a repair that requires a professional solution to be done safely so that your new tanks provide reliable service for many years.

Replacing Grand Banks fuel tanks improperly can result in

- FIRES – one recent Grand Banks was totaled by a fire during fuel tank removal in a quality yard that didn’t have the experience needed on tanks

- RELIABILITY ISSUES – the new tanks require extensive new hose and coupling work which, if done poorly, will plague you for years

- HIGH COST – there is a wrong way and a right way to replace these tanks. We have a proven process to cut them out and install new tanks without removing engines or cutting holes in the hull. In the long run, an experienced yard will save you money

Replacing Grand Banks Fuel Tanks the Easy Affordable Way

These tanks are enormous and expensive to remove but there are easy and hard ways to do it. Many yards are actually cutting the sides or the bottom out of the boat to replace them. There is no reason to destroy the integrity of the hull to replace the Grand Banks fuel tanks. We have found a way around this with a solution that accomplishes the job safely and result in a reliable long-term solution.

Our process is proven with hundreds of fuel tanks replaced since we started replacing tanks in the early 1990s on the boats built in the 1970s. We cut out the tanks with a proven preparation process that makes them safe to cut. Once they are removed, we have multiple sources for new tanks, usually in aluminum. Your configurations may be horizontal, vertical, and any design of your new fuel distribution system.

Six to ten weeks are normally required for a Grand Banks tank replacement job. There are times when we have done them quicker to meet the needs of a customer and with early availability of the new tanks. Patience is mandatory if it’s to be done safely and professionally.

Our costs are the lowest in the business because we have done it successfully so many times.

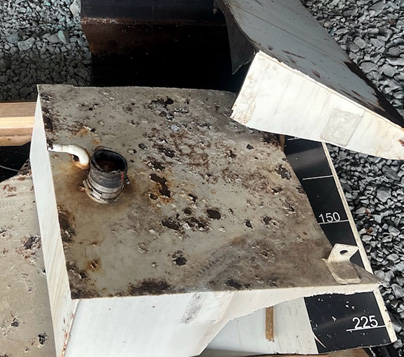

Before

After

The “After” view here is a 1988 Grand Banks with a fuel tank dual installation we did in 1996. The paint is so perfect on these tanks there is not so much as a scratch or hint of exposed or metal weld deterioration.

Why Do Grand Banks Fuel Tanks Leak and Rust?

Why Do Grand Banks Fuel Tanks Leak and Rust?

The major sources of leaks in fuel tanks are from:

- Water leaking onto them, often from leaking seams around the fuel fill fittings or generally leaking and degraded teak decks above the tanks

- Too much heat created by not enough airflow in the engine room. Excessive heat dries out the teak deck above the engine room and accelerates deck leaks. Running your blowers can reduce this effect and be an important part of your teak deck and therefore fuel tank preservation

- Fuel is left in the tank too long and moisture collects in the bottom

- Improperly coated. Tanks need a good epoxy coating to give a long life

- Sludge buildup inside from general lack of maintenance or following small leaks on the top of the tank. Any water buildup in the tanks causes sludge and accelerated pitting corrosion in the tanks and particularly the bottoms

- Support structure wet crevice corrosion from water leaks onto the wood supports that the tanks sit on

- Engine exhaust hoses, elbows, and hoses on some early Grand Banks models are notorious for leaking with small drips causing pitting corrosion in a small, localized area

The use of Diesel Kleen or Biobor will control the organisms that thrive on affected fuel. Use of water removal chemicals, sludge preventing chemicals and Biobor routinely will result in perfectly clean fuel and low sludge buildup in your tanks.

Flushing the tanks and polishing the fuel every three to four years to prevent a buildup of sludge can go a long way. Sludge is the #1 cause of internal degradation. Some other easy things that can be done to keep water and sludge out of your tanks are:

- Rebed the fuel fill hardware

- Seal the air vent in winter

- Annually verify that no water is in the bottom of your tanks

For tanks that are not leaking yet, inspect the tanks frequently by having above average lighting illuminating the tank sides. Make sure exhaust water leaks do not abraid the paint and setup a site for pitting corrosion. When tanks are new they should be coated with an appropriate two part Epoxy Primer and Polyurethane two part paint. Older tank tops can be painted but preparation is very tough. Doing a poorly prepared paint job will NOT stop the corrosion underneath and is not recommended.

Dickerson Harbor Boatyard Has the Solution to Leaking Grand Banks Tanks

Over the past 50 years, working with Grand Banks boats in new and preowned sales, commissioning, storing and servicing, we have learned about the tanks, fuel or water and what the tanks need for maintenance. At Oxford Yacht Agency we have developed strategies for maintenance, repair and replacement

Over the past 50 years, working with Grand Banks boats in new and preowned sales, commissioning, storing and servicing, we have learned about the tanks, fuel or water and what the tanks need for maintenance. At Oxford Yacht Agency we have developed strategies for maintenance, repair and replacement

Leaking fuel tanks need to be replaced and our process does that without cutting holes in the hull or removing engines. Done correctly, Grand Banks tank replacement is a straightforward repair that is both SAFE and AFFORDABLE.

We strongly recommend against temporary repairs by patching or cutting inspection holes in the tanks and later mounting a cover. Those repairs are unsafe and will dramatically reduce the value of the boat on resale. Leaking fuel in your bilges or overboard is not a trivial problem. You need professional help that has successfully done this job many times before.

Removing the Leaking Grand Banks Fuel Tanks

Protecting your beautiful Grand Banks exterior and salon interior is very important during this nasty job. We have a proven system for that too so no additional work is created for the owner.

A good quality Grand Banks fuel tank replacement will require these key steps and associated equipment.

- Sawzall for smaller jobs

- Plasma cutting for larger tanks

- Great ventilation of the job site

- Safety considerations (There have been recent fires in other boatyards doing this job)

- Repainting with epoxy

- Replacing the surrounding insulation

- Replacing exhaust hoses

Design, Purchase, and Delivery of New Fuel Tanks

Our solution to the new tank replacement is typically to use four tanks instead of the standard two. The total capacity is not changed, but the smaller tanks are able to be brought into the boat through the hatch (and removed the same way if that need ever arises). Our tanks are rust-treated and Awlgripped for maximum longevity.

Designs for the tanks and new fuel system is flexible depending on the owner’s preferences and cruising needs. Usually, two tanks are stacked vertically on each side with a large connecting hose joining each stack. Occasionally we use a horizontal stack with two tanks on each side. Most of our tanks are aluminum from several high-quality manufacturers that we have dealt with for years.

Any design starts with detailed measurements of the existing space, support structure, and all adjoining components. This starts as soon as the boat comes in the yard and continues until we have all the detail we need.

Any design starts with detailed measurements of the existing space, support structure, and all adjoining components. This starts as soon as the boat comes in the yard and continues until we have all the detail we need.

In the finished installation we try to leave clearance room to access the tops of the tanks. In the original installations, there is only a small clearance between the tank tops and the bottom of the deck. New tanks, if designed correctly, can be visually inspected and if any deck leaks occur they can be spotted and fixed with minor difficulties.

Stainless fuel tanks have never been endorsed by the US Coast Guard for commercial boats or passenger carrying vessels. Stainless fuel tanks are nice, but they are expensive and still need to be maintained. We do occasionally source stainless thanks for those customers who want the best quality and are planning to keep their boats for many years.

Lead times are currently running 4 to 6 weeks for the tanks. Our removal and installation typically takes 6 to 10 weeks. The job takes time to be done safely and with perfect results.

There are some times when tanks are in stock for more simple installations.

Lead times are currently running 4 to 6 weeks for the tanks. Our removal and installation typically takes 6 to 10 weeks. The job takes time to be done safely and with perfect results.

There are some times when tanks are in stock for more simple installations.

Our usual tank level system is a more modern push button sight tube system. Smart switch fuel and water tank components are available, and the new tanks can be configured to fit any new system as they are being manufactured. One of the features of working with us is the design flexibility to make improvements to the fuel distribution system.

Tanks are fragile! The best shipping arrangements require planning. We like to have owners pick up or meet us part way and transfer trailer to trailer if possible if we are delivering the tanks for another yard to install.

Often, we will assist customers with shipping by renting a U Haul trailer that can be towed to meet a customer and they can continue towing it along to reach Michigan, Cape Cod or Maine while minimizing handling and having more expensive insurance.

Preparation of the Vacant Original Space

While the tanks are out, it is a good opportunity to do some serious engine room clean up. The hull sides behind and around the tanks will be painted, the hoses and wiring checked, and everything made spotless. We typically use a base of solid PVC sheet for the tanks to rest on which is more affordable than painted plywood with the added benefit of being virtually non-permeable to diesel fuel and water.

While the tanks are out, it is a good opportunity to do some serious engine room clean up. The hull sides behind and around the tanks will be painted, the hoses and wiring checked, and everything made spotless. We typically use a base of solid PVC sheet for the tanks to rest on which is more affordable than painted plywood with the added benefit of being virtually non-permeable to diesel fuel and water.

We always recommend replacing a lot of the old acoustical soundproofing with a foil-faced lead lined sound insulation. The more modern insulation is fully fireproof which the old insulation is definitely not. In fact, the old insulation can be a fire hazard when cutting or welding nearby and it can smolder for hours before the fire grows.

Installing the New Grand Banks Fuel Tanks

The major key to successful installation is to be extremely careful and methodical so that there are no scratches or dents in your perfectly painted tanks. This is not an easy task with the engines in place and without hull cuts to make a much more complex job. Our personnel have superior patience to get these new tanks in and mounted without a scratch, literally.

The major key to successful installation is to be extremely careful and methodical so that there are no scratches or dents in your perfectly painted tanks. This is not an easy task with the engines in place and without hull cuts to make a much more complex job. Our personnel have superior patience to get these new tanks in and mounted without a scratch, literally.

Once the tanks are in place and fully supported in their final resting places, the final work of installing hoses, re-running any removed wiring, and installing all the valve manifolds to have a maximum flexible fuel distribution system. At times, the Racor filters are remounted, and custom valve manifolds are installed. Changing filters with one of our systems is a breeze. Also, the flexibility for all different distribution configurations can make easy work if one tank gets contaminated or you have to run on one engine for a long period of time.

Every hose and wire is inspected to be sure it fits perfectly, there is no rubbing with Grand Banks quality of supports. Every fitting on the tanks is tested and we guarantee you will leave the yard with no fuel leaks. That said, owners will have to frequently inspect the new systems as you cruise to make sure no fuel or air leaks develop. Our track record of quality on Grand Banks fuel tank replacements is extremely high.

CALL NOW – 410-822-8556

for more information and talk to our owner John Shannahan

The problem of rusting fuel tanks

The problem of rusting fuel tanks How can you tell if your tanks actually need replacing?

How can you tell if your tanks actually need replacing?