Grand Banks yachts are known for their long skeg keels which protect the running gear and rudders when the inevitable soft grounding occurs. This is a great feature and one very much appreciated by Grand Banks Owners. These keels are also one of the most frequent serious hull repairs we do. One of our specialties at the Dickerson Harbor Yard is Grand Banks Keel Repairs.

Damage to a keel on any of the Grand Banks models is serious, even when minor. We see a lot of boats that had a minor damaged spot on the keel, but it’s been left alone or poorly repaired so water leaks into the keel. That risks a lot more serious damage to the foam inside and the surrounding glass. Even without a grounding, some keels get water in them from leaks created by screw holes in the bilge after years of DIY installations.

One of the most common causes for keel damage is mooring the boat on a coral ledge or outcropping with a falling and rising tide. After a few cycles, the stress concentration in one area of the keel starts cracking the fiberglass. This cycling over days or weeks can easily cause a damaged area like you see below.

Here is a perfect example of recent keel damage that has been left not repaired. In fact, a drain assembly has been installed right next to the damaged keel area. This is a keel that needs immediate and professional repairs before a lot more serious damage occurs.

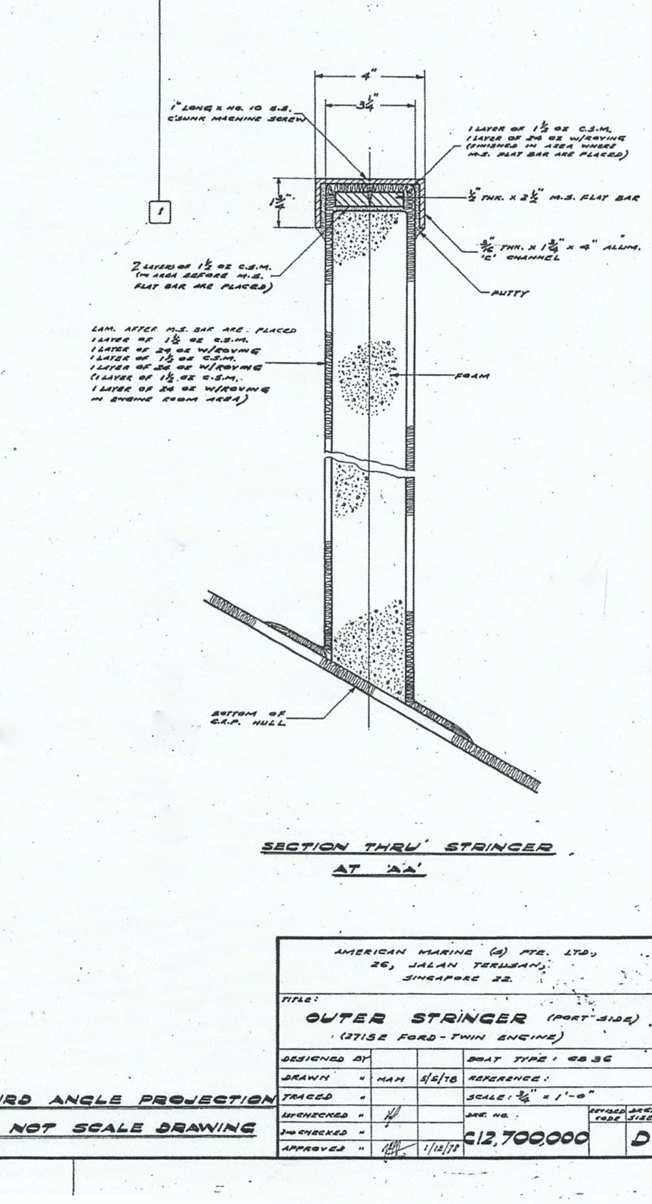

This damaged area and the drain should be ground out until good, solid fiberglass is found. Then both holes need to be glassed up in accordance to this lamination schedule from the Grand Banks 36 stringer drawing. This drawing is hard to read but zoom in and you will see a detailed 7-step fiberglass lamination schedule for the strongest part of the boat, the stringers. Repairing your keel to this standard will ensure proper restoration of the keel strength and be a permanent repair for another 40 or 50 years.

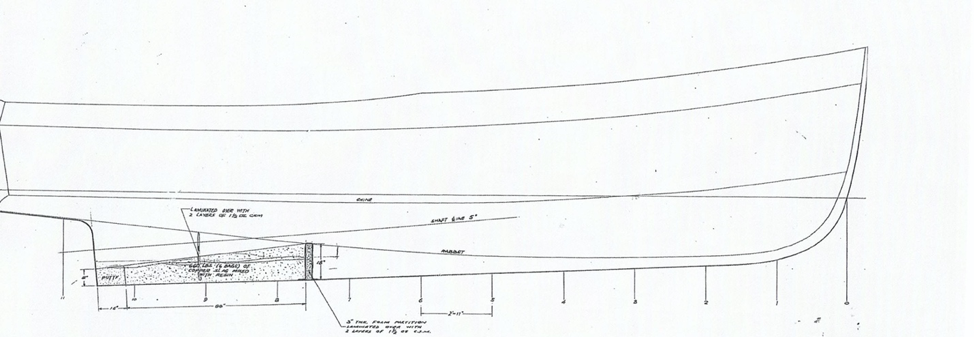

Here is a diagram, from the GB36, which shows the general construction of the keel. This is essentially the same for all the early Grand Banks models. Although it’s a bit hard to read, it shows that the aft part of the keel is filled with a cooper and resin mixture. The forward part of the keel is foam filled. This foam should be fully dry before any repair is completed. In the first keel picture at the top of this blog, you can see an example of a serious insurance repair we completed, this is the step where all the foam has been removed and one whole side of the keel has been opened up. Not all repairs are this serious and can be easily resolved if fixed early and correctly.

If you have questions about a hull, keel, or structural repair on any Grand Banks model, we have drawings and over 45 years of expertise in the proper repairs. Call for consulting help or bring your boat to our Dickerson Harbor Boatyard for repairs and any modernization you may need.